Certifications

Constant power parallel circuit heating cables provide constant power in watts per metre both as the temperature and their length vary. They can therefore be cut, spliced, branched and adapted to actual requirements directly on site at the time of their installation.

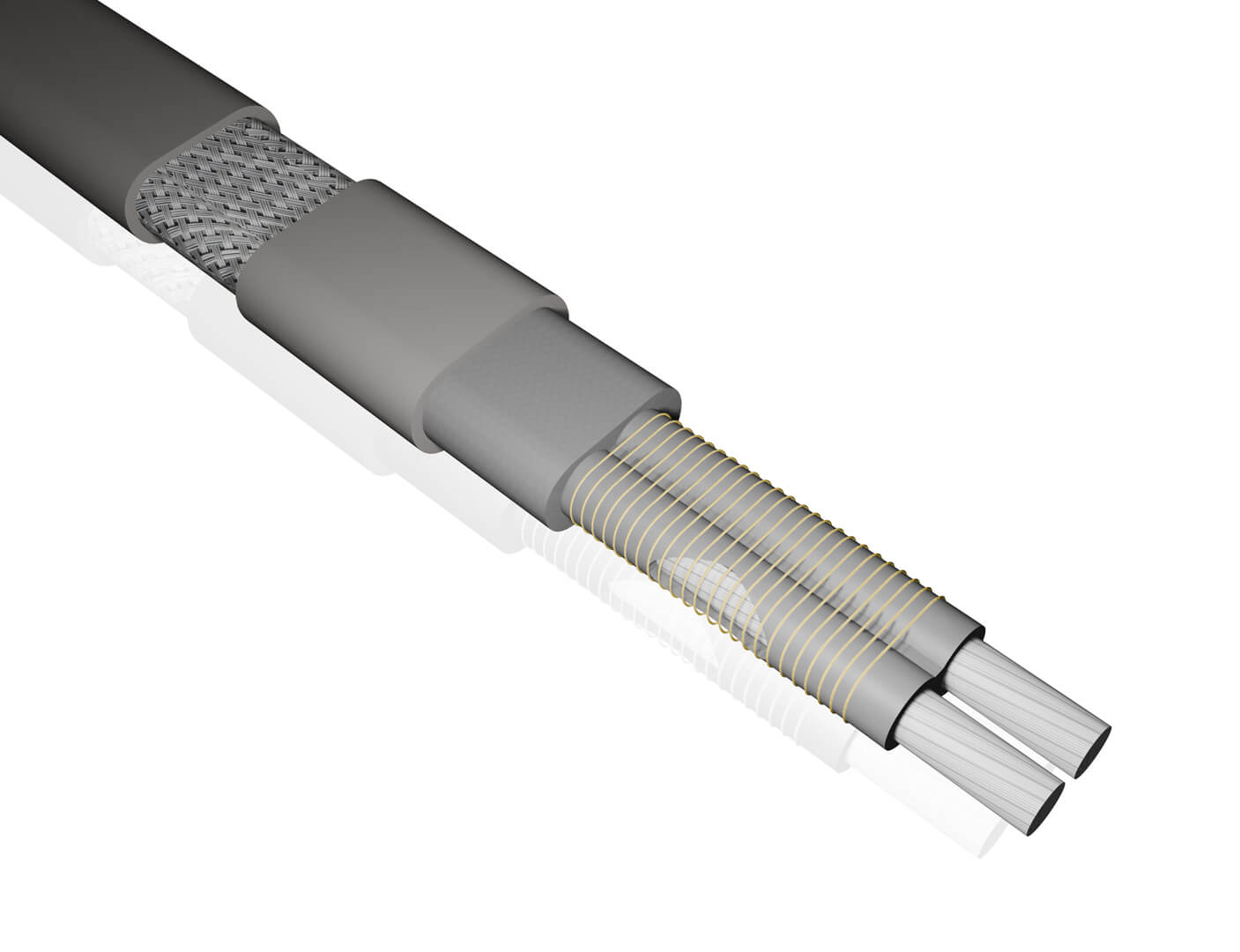

A nickel-chrome wire or other similar alloy, which constitutes the heating element, is wound onto two conductors of suitable cross-section and insulated with silicone rubber or fluorine polymer. This conductor wire is brought into electrical contact alternately with the two conductors at regular intervals (active zone) by soldering.

Then, a protective sheath of silicone or fluoropolymer or high temperature mica tape is extruded over the cable, as well as a metal mechanical protection sleeve and earthing braid and finally a further outer sheath made of fluoropolymer or other material resistant to corrosion or high temperatures.

Constant power cables always require a control thermostat not only for accurate process temperature control but also to avoid overtemperatures that would cause damage.

Advantages:

- No need for oversized start-up absorption protections

- Can be used in safe and explosive zones and in corrosive environments

- High performance per metre even at high temperatures

- Can be cut, terminated and spliced on site to the actual pipe length

Examples of application:

- Maintaining products with temperatures up to 300°C

- Antifreeze even on steam pipes with operating temperatures of 350°C

- Particularly suitable for industrial processes when the temperature to be maintained is high

Request an Online Quote now

For more information on our products and areas of application, please do not hesitate to contact us, we will provide you with all the details you need.